Debavurare

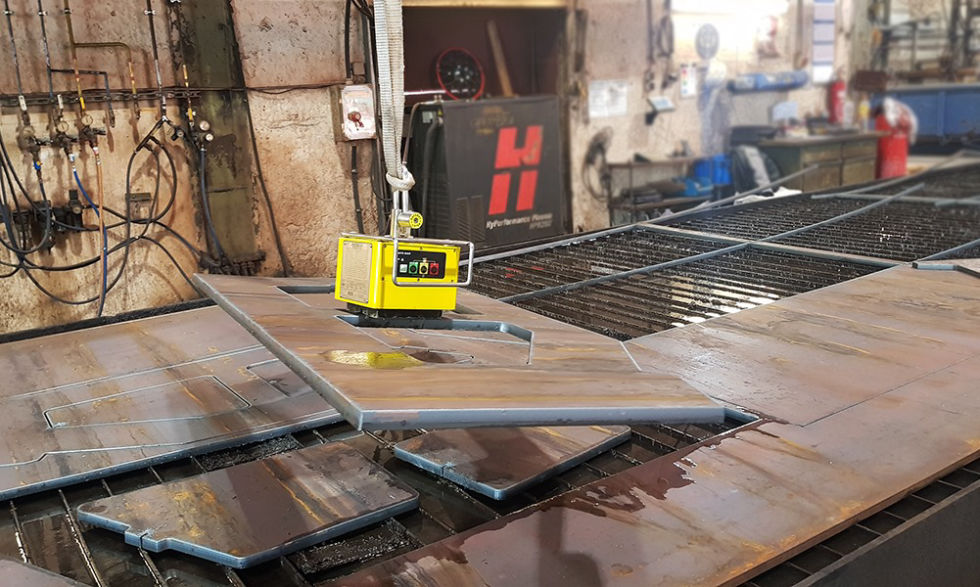

Debavurarea foii de metal este indepartarea metalului proeminent si a marginilor ascutite dupa taiere. Aceste bavuri sunt bucati mici de metal lipite de obicei pe margini. Acestea sunt cauzate de metode de taiere precum laser, jet de apa, plasma, precum si pentru piese perforate. Multe companii se bazează astazi pe debavurare automata. Masinile moderne de debavurare au diverse unitati de procesare care pot fi echipate cu diferite materiale abrazive. In functie de cerinte, sunt disponibile diferite masini si/sau configuratii pentru a obtine rezultatul necesar de debavurare pentru curatarea marginilor metalice. Astfel, masinile moderne de debavurare produc muchii metalice curate pentru prelucrarea sigura si eficienta in aval a pieselor din tabla. Solutii la Cheie --> Debavurare + Rotunjirea marginilor + Indepartarea oxidului laser + Indepartarea zgurii + Finisarea suprafetelor